|

|

|||

Gasifiers once solved energy problems - they might, yet again. |

|||

|

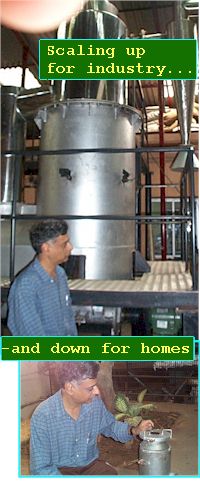

For over 20 long years Dr. H. S. Mukunda of Indian Institute of Science [IISc], Bangalore has devoted his attention to an obdurate lad of much promise in the world of alternate energy sources - the gasifier! Step by patient step, he has made it a viable technology and a critical scientific community is beginning to take notice. Gasifiers were darlings of the petroleum starved world during the war years of the 1940s. Despite the problems that riddled them, people endured them since they burnt wood chips or coal to produce gas that drove trucks and buses built originally for petrol and diesel. Once the war was over they were forgotten -- with a sigh of relief -- except by a few enthusiasts. The first spark: As interesting as the story of the gasifier's rebirth, is that of Mukunda himself. He is of that breed of Indians who come from modest backgrounds, educate themselves, arrive at fields of study that are global in vision and proceed to make their mark. Mukunda is one of the several thousand Indians who quietly work away with dedication and reinforce hope in the future of the country. He was born in Hunsur in Mysore district where his father was a school teacher. Powered by nothing more than intellect and diligence, he had arrived -- a graduate engineer just out of his teens -- at IISc in 1969 for his masters work. By 1969 he had earned his doctorate in Combustion Engineering and joined the IISc faculty. His adventures with gasifiers began in 1981 when Dr. A. K. N. Reddy -- a venerable elder at IISc -- was trying to interest several young scientists there in energy issues. The idea was to re-explore non-petroleum energy sources -- such as wind, solar, biomass etc -- that had been abandoned by a lazy world. Earlier in 1975, the Karnataka State Council for Science and Technology [KSCST] had begun to support research effort in these areas. Dr. Satish Dhawan the then Director of IISc was an enthusiast for the programme too. Thus in 1981, when Dr. Reddy spoke to young Mukunda about the potential of gasifiers, it was happily a time when many interests had converged and created the right climate. Mukunda's fire was lit. A technology primer: "Solar energy captured by photosynthesis and stored in biomass can be converted by the process of gasification into a high-energy fuel that can be used in internal combustion engines for power generation," says Dr. Mukunda. The combustible gas -- popularly, producer gas -- is composed of about 20% Hydrogen, 20% Carbon Monoxide, 3% methane, 10% Carbon di Oxide and the rest Nitrogen. "The gas will fuel a spark-ignition engine delivering about 60% of the power of gasoline, or it will run a combustion-ignition [diesel] engine in dual-fuel mode, eliminating the need for 75 to 85% of the diesel fuel." Obviously the promise was vast. But the equipment then, was strewn with problems. Gas production was erratic, the gasifier quickly clogged with tar and consequently maintenance was frequent and messy. Gasifier design called for getting too many conflicting elements right and that's what tired researchers. Around the same time as IISc began to be interested, in far Colorado, USA Dr. Thomas B. Reed was also conducting his re-examination of the old promise. Dr. Mukunda credits him with many of the insights that have revived the gasifier. Till the 1980s the gasifier was broad in diameter, stood short, and was loaded with wood chips by opening the top, which was then closed. The thermal paths within were biased and not all of the wood chips was utilised in the process. The key parameters in gasifier design are the diameter of the machine, its height, the 'throat' from which the gas issues, the ports through which air is supplied and the construction materials chosen. Further, if the technology was to be seriously considered for power production, issues like ease of feeding the gasifier, hours between maintenance, level of skill required in operating them and cost competitiveness had to be looked to. The Bangalore version: In the early 1980s a 'study-model' was built at IISc and observations began. The debate in the gasifier world then, in the main concerned three areas: the virtues of closed top models versus the open top, how the 'throat' was to be designed and how tar build-up was to be minimised and slowed. In May, 1985 the Bangalore version was ready. It addressed many of the problem areas and incorporated many departures from past practice. It was a small diameter, tall machine with an open top. The 'throat' was nearly non-existent. A single air-feed nozzle was set at a calculated angle, replacing a set of horizontal ones that was the current practice. It employed a 'reburn' process to fully burn the feed, reduce tar build-up and improve efficiency. Ceramic lining components were proposed. [Click for a technical illustration] In operation, this version worked longer hours between maintenance than was the current experience then. Encouraged, the team began to experiment with several types of fuel and the classical old 'wood' gasifier soon became a 'biomass gasifier'. The idea was to make use of India's abundant and varied biomass. Mukunda estimates that we generate 6 to 10 MT of usable urban waste per hectare per year. This too can now be pelletised and used as an alternate source of energy. CGPL is born: In 1972 Mukunda's work having attracted sufficient interest, Combustion, Gasification and Propulsion Laboratory [CGPL] came into being in the IISc campus. Funded largely by the Department of Non-Conventional Energy Sources [DNES], CGPL has been at work tweaking the gasifier design, scaling it up, commercialising it, creating intellectual property [it has 6 patents] and popularising it. Mean hours between overhauls have risen from 1200 hours to the current 2500 hours. Feeding of the gasifier has been automated and integrated systems have been built. Mukunda's team has models all the way from 3.5 kW for farms to nearly 1 mW for industries. The big break came in 1994. Dr.Hari Sharan a legendary name in power engineering had left India's BHEL and had joined DASAG, Switzerland. On one of his visits to India he saw Mukunda's gasifier and was excited. "Are you open to an independent evaluation?," he asked. Mukunda was. Soon, 4 men arrived from Switzerland and tests devised by them began and lasted over 12 days. A European gasifier then would gum up in 10 to 15 minutes; the Bangalore machine lasted 100 hours. The Swiss were impressed and a gasifier incorporating Indian innovations was on its way overseas [Chatel St.Denis, Switzerland]. Soon an order came from far Chile [Butachaques Island]. In India meanwhile, a one megaWatt plant is being planned. Arati HiTech Biopower, Sultanpet plans to use coconut shells available in the neighbouring areas, as feed. The plant will produce electricity and coconut shell charcoal, a high value industrial product. The outlay for the project is Rs.3.5 crores. [For a complete list of installations click here] Amidst all this, the village boy Mukunda has not forgotten his origins. As we end the tour of his rambling workshop, he holds out a tiny application. "This too is a gasifier," he says. "It is a domestic stove for rural India that can be fuelled by fallen leaves. It is in fact a simple upside down gasifier that gives a clean smoke-free blue flame. I hope it will help reduce the practice of lopping off branches and felling trees for household cooking."

Dr H S Mukunda CGPL Indian Institute of Science Bangalore - 560 012 eMail: mukunda@cgpl.iisc.ernet.in Phones: 01-80-3600536; 3092338; 3092645 & 3601144[Home] December 2001

|

|

||